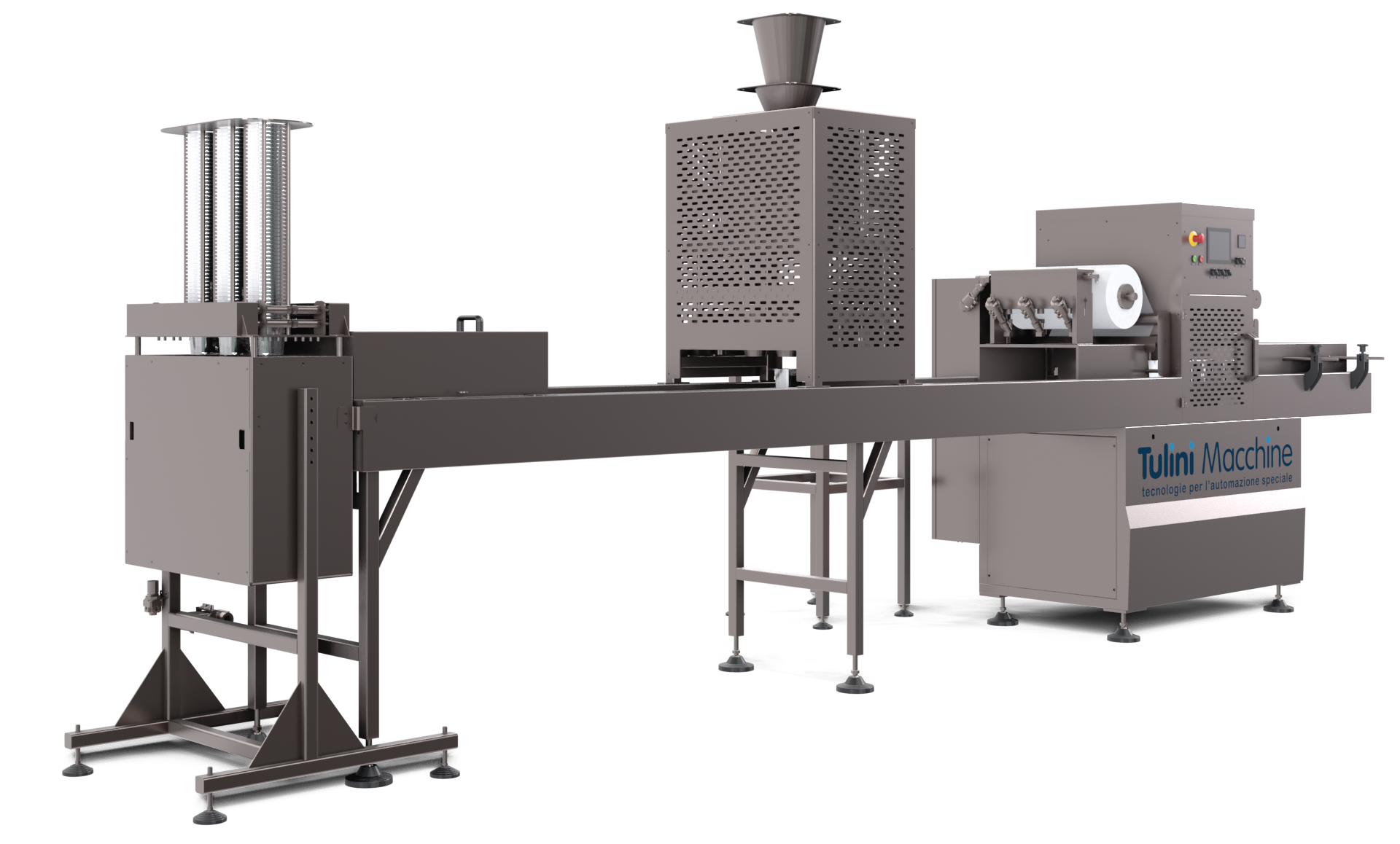

TRAY SEALER MACHINE TM 150

Tray sealer machine

TM 150

drag to rotate

product description

The V/G Tray sealer machine model TM150 is a fully automatic, sturdy and reliable machine made entirely of stainless steel.

Unwinding and rewinding of the upper film by integrated motorized roller is automatic and ensures precision in film centering .

The length of film to be unwound is programmable via PLC in order to reduce waste.

The diagnosis and alarm system enables fast and accurate control of machine functions.

The design based on a modular concept, allows the integration of a variety of options.

The electrical and pneumatic components are enclosed and integrated to the cabinet and therefore do not come in contact with the working environment. This choice allows us to guarantee the life of the plant components and simplify maintenance operations by reducing intervention time.

The molds are designed to simplify disassembly, tooling and maintenance. In fact, they can be removed from the machine without the use of tools in a really short time.

ACCESSORIES*

– Destacker for trays

– Loading hoppers

– Scales

– Dispensers for oil and governing liquids

– Alignment devices for tray outlet

sold separately*

DIMENSIONS

2500 X 1000 X 1400 MM

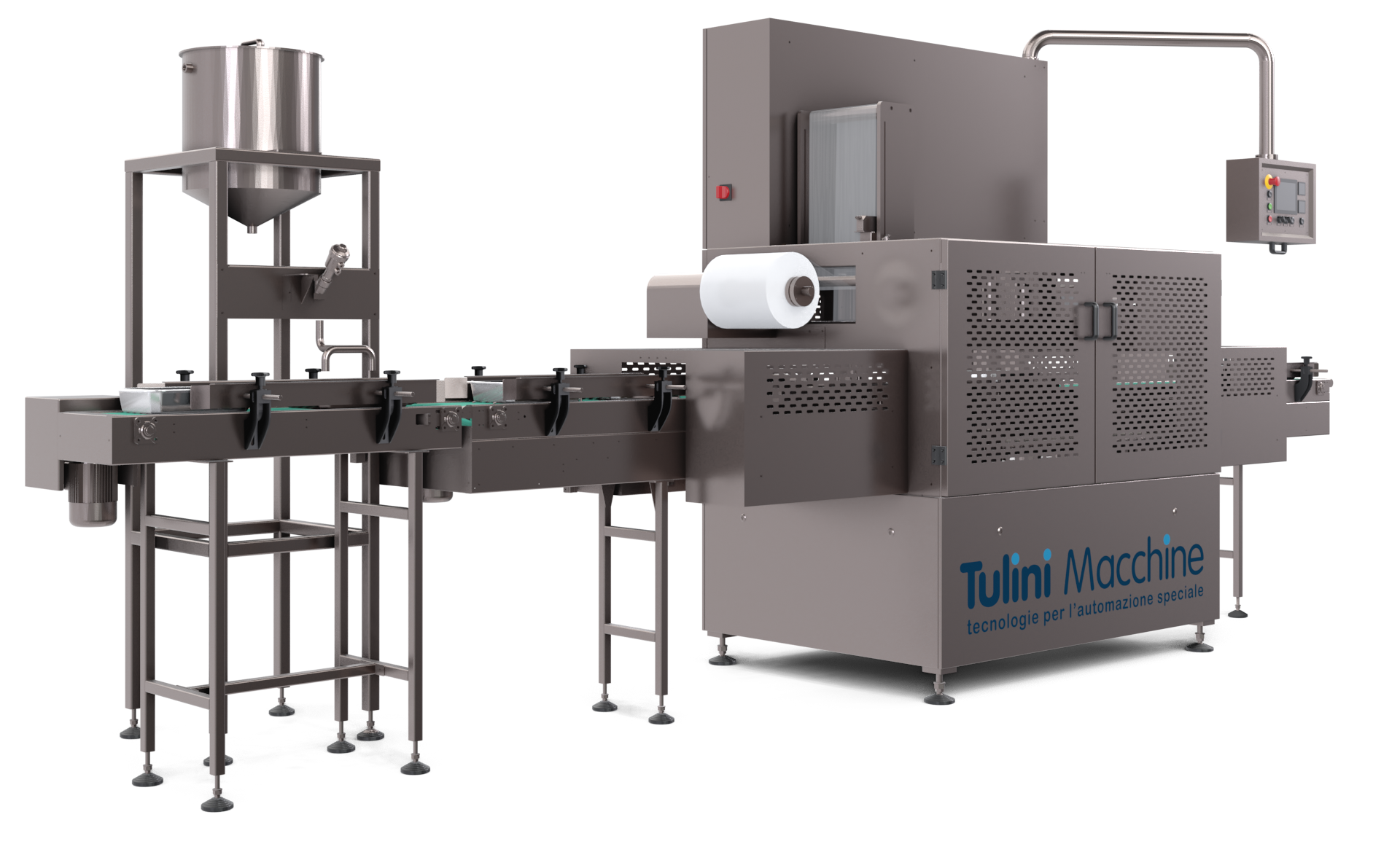

product description

The V/G Tray sealer machine model TM150 is an extremely compact , sturdy and reliable machine made entirely of stainless steel.

Unwinding and rewinding of the upper film by integrated motorized roller is automatic and ensures precision in film centering .

The length of film to be unwound is programmable via PLC in order to reduce waste.

The integrated diagnostic system enables quick and effective verification of machine status by promptly notifying the operator of actions to be taken.

The design based on a modular concept, allows the integration of a variety of options.

The electrical and pneumatic components are enclosed and integrated to the cabinet and therefore do not come in contact with the working environment. This choice allows us to guarantee the life of the plant components and simplify maintenance operations by reducing intervention time.

The molds are designed to simplify disassembly, tooling and maintenance. In fact, they can be removed from the machine without the use of tools in a really short time.

OPTIONAL ON REQUEST

– Stackers for trays

– Loading hoppers

– Scales

– Dispensers for oil and governing liquids

– Printers / Labelers

– Tray aligners 2-1 / 3-1 / 4-1

REQUEST A QUOTE